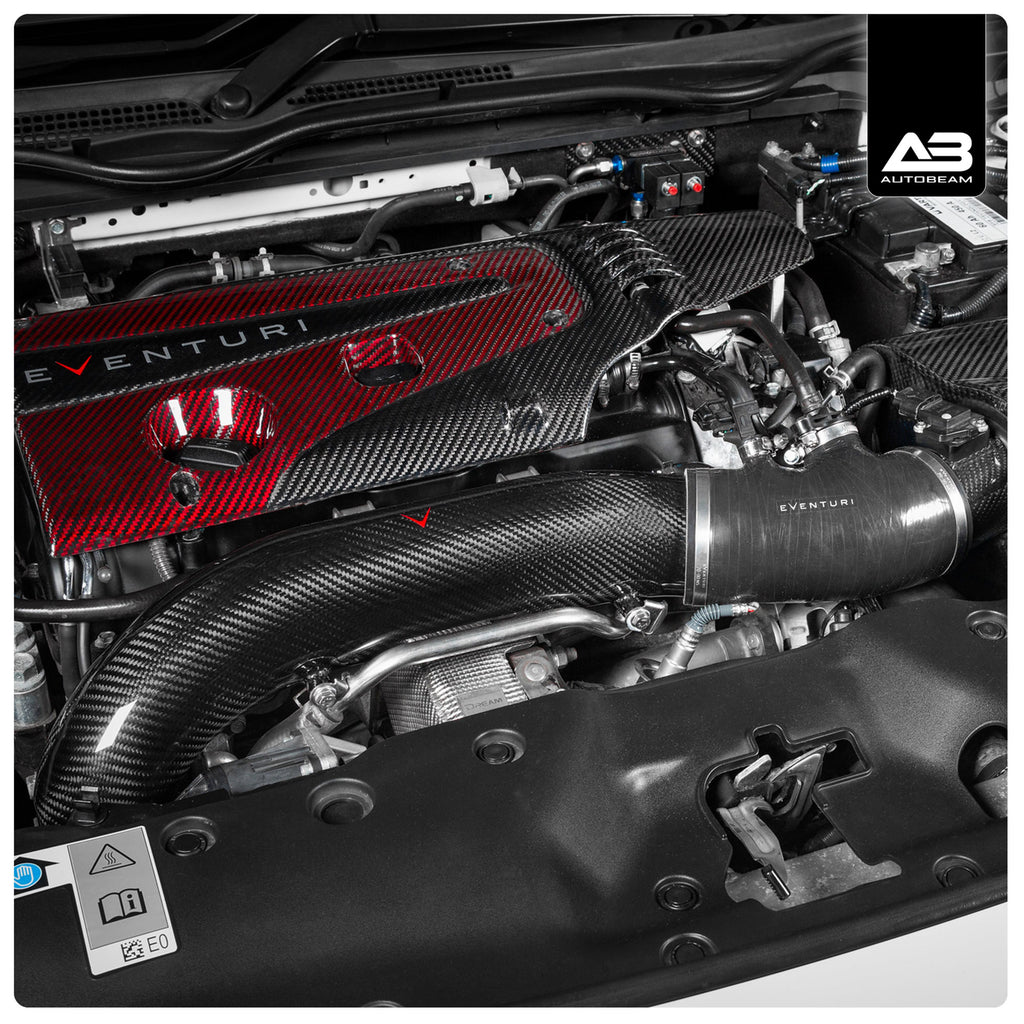

Introducing our updated Carbon Turbo Tube for the FK8 which is now even larger in volume, allowing the turbo to function with even less restriction and therefore unleashing even more power.

|

- Information

- Fitment

- What's in the box

- Shipping

- Reviews

Crafted from Prepreg Carbon Fibre, the Turbo Tube is a one-piece design to maintain a smooth flow path to the turbo. It has an inlet diameter starting at 78mm internally and then increasing to 88mm across the main body of the tube before tapering down to the turbo inlet flange. The stock turbo tube in comparison only has an internal diameter of 63mm. This difference in size equates to an increase in cross sectional area of over 96% at its largest point. Furthermore, since it is made from Carbon, it has a much lower weight and lower thermal conductivity across the wall thickness than the stock cast aluminium tube.

Our silicon joiner hoses have been made to ensure a perfect fit and also to maintain smooth internal airflow. The main silicon hose at the inlet side has an internal step which mates against the turbo tube thus eliminating the potential of turbulence against the exposed wall thickness of the tube. The turbo coupler has a silicon spacer ring which separates the carbon from the metal turbo flange. This acts as a thermal barrier to reduce heat conduction from the hot turbo flange through to the carbon tube.

CNC machined from aircraft grade aluminium and anodised, our flange provides a perfect fitment and seal against the stock turbo.

Inlet Diameters – Eventuri 78mm at the intake end, increasing to 88mm VS Stock 63mm. Starting at the connection to the intake system, we have matched the MAF tube diameter and this now increases to 88mm through the main section of the tube giving an increase in cross sectional area of 96% compared to the OEM tube. Clearly with significantly larger internal diameter sizes, the Eventuri tube encapsulates a much larger internal volume which de-restricts the flow path to the turbo. This allows the turbo to operate more efficiently and spool up to peak boost levels faster. It also allows the turbo to operate at peak boost with less turbine loading.

Having just a large internal volume is no good unless the flow path also allows for smooth airflow to the turbo. By using high temperature Prepreg Carbon Fiber we have managed to achieve a smooth internal surface. In contrast, the stock inlet tube is made from cast aluminium which ends up with a rough internal surface. This coupled with the smooth curvature of the elbow results in a flow path which minimises turbulence.

The final criteria was to minimise the conduction of heat into the airflow. The stock inlet is directly connected to the turbo and so immediately conducts heat as the turbo spools. Our system uses a machined flange which connects to the turbo and then a silicon coupler with an integrated thermal spacer to keep the carbon elbow from having direct contact with the turbo. This barrier coupled with the low through-thickness thermal conductivity of carbon fiber results in less heat being transferred to the airflow.

Carbon Fibre Turbo Tube with integrated Carbon Brackets

Custom Silicon Joiner at intake side

CNC Machined Turbo Flange

Custom Silicon Coupler at Turbo Side

Autobeam | Autoprint | Auto Finesse

Orders placed before 1pm

Processed & shipped the same day unless otherwise stated.

Orders placed after 1pm

Processed & shipped the next working day.

Orders placed after 1pm on a Friday.

Processed & shipped the following Monday.

Orders are shipped Monday-Friday only.

All other brands

In stock items normally delivered within 1-3 days. Items made to order can be upto several weeks.

Stock for all other brands are not monitored therefor may be out of stock.

Information

Crafted from Prepreg Carbon Fibre, the Turbo Tube is a one-piece design to maintain a smooth flow path to the turbo. It has an inlet diameter starting at 78mm internally and then increasing to 88mm across the main body of the tube before tapering down to the turbo inlet flange. The stock turbo tube in comparison only has an internal diameter of 63mm. This difference in size equates to an increase in cross sectional area of over 96% at its largest point. Furthermore, since it is made from Carbon, it has a much lower weight and lower thermal conductivity across the wall thickness than the stock cast aluminium tube.

Our silicon joiner hoses have been made to ensure a perfect fit and also to maintain smooth internal airflow. The main silicon hose at the inlet side has an internal step which mates against the turbo tube thus eliminating the potential of turbulence against the exposed wall thickness of the tube. The turbo coupler has a silicon spacer ring which separates the carbon from the metal turbo flange. This acts as a thermal barrier to reduce heat conduction from the hot turbo flange through to the carbon tube.

CNC machined from aircraft grade aluminium and anodised, our flange provides a perfect fitment and seal against the stock turbo.

Inlet Diameters – Eventuri 78mm at the intake end, increasing to 88mm VS Stock 63mm. Starting at the connection to the intake system, we have matched the MAF tube diameter and this now increases to 88mm through the main section of the tube giving an increase in cross sectional area of 96% compared to the OEM tube. Clearly with significantly larger internal diameter sizes, the Eventuri tube encapsulates a much larger internal volume which de-restricts the flow path to the turbo. This allows the turbo to operate more efficiently and spool up to peak boost levels faster. It also allows the turbo to operate at peak boost with less turbine loading.

Having just a large internal volume is no good unless the flow path also allows for smooth airflow to the turbo. By using high temperature Prepreg Carbon Fiber we have managed to achieve a smooth internal surface. In contrast, the stock inlet tube is made from cast aluminium which ends up with a rough internal surface. This coupled with the smooth curvature of the elbow results in a flow path which minimises turbulence.

The final criteria was to minimise the conduction of heat into the airflow. The stock inlet is directly connected to the turbo and so immediately conducts heat as the turbo spools. Our system uses a machined flange which connects to the turbo and then a silicon coupler with an integrated thermal spacer to keep the carbon elbow from having direct contact with the turbo. This barrier coupled with the low through-thickness thermal conductivity of carbon fiber results in less heat being transferred to the airflow.

Fitment

What's in the box

Carbon Fibre Turbo Tube with integrated Carbon Brackets

Custom Silicon Joiner at intake side

CNC Machined Turbo Flange

Custom Silicon Coupler at Turbo Side

Shipping

Autobeam | Autoprint | Auto Finesse

Orders placed before 1pm

Processed & shipped the same day unless otherwise stated.

Orders placed after 1pm

Processed & shipped the next working day.

Orders placed after 1pm on a Friday.

Processed & shipped the following Monday.

Orders are shipped Monday-Friday only.

All other brands

In stock items normally delivered within 1-3 days. Items made to order can be upto several weeks.

Stock for all other brands are not monitored therefor may be out of stock.

Reviews